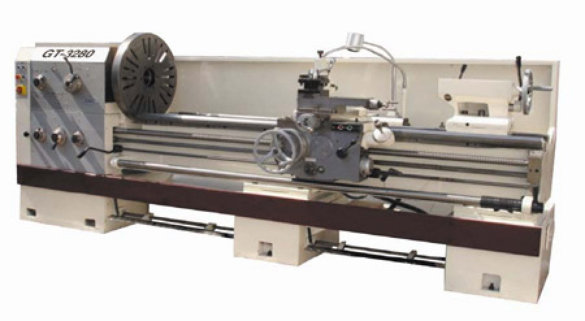

| GMC LATHE | Specifications |

| Model | GT-3280 , GT-32120 |

| Size | 32" x 80" , 32" x 120" |

| Swing over bed | 32" |

| Distance between centers | 80" , 120" |

| Max swing over cross-slide | 22-1/16" |

| Max swing in gap | 39-1/2" |

| Width of bed | 20-1/2" |

| Effective length in gap to spindle | 10" |

| Effective length in gap to chuck jaws | 7" |

| Spindle hole dia. | 4-1/8" |

| Spindle mount | |

| Taper of spindle center | MT # 6 |

| Spindle speeds ( 12 ) | 30 - 1400 RPM |

| Longitudinal feeds | 0.0023 - 0.93 IPR, 65 kinds |

| Cross feeds | 0.0011 - 0.04 IPR, 65 kinds |

| Threads | Details |

| Inch threads | 28 - 2 TPI 27 kinds |

| Metric threads | 1 - 14 mm , 22 kinds |

| Diamentral pitch threads | 56 - 4 DP , 24 kinds |

| Module threads | 0.5 - 7 MM , 18 kinds |

| Carriage | Details |

| Maximum travel of top slide | 5-3/4" |

| Maximum travel of cross-slide | 17" |

| Longitudinal rapid traverse | 18 ft / Min |

| Cross rapid traverse | 8 ft / Min |

| Tailstock | Details |

| Diameter of tailstock quill | 3" |

| Maximum travel of tailstock quill | 6" |

| Taper of tailstock quill center | M.T. # 5 |

| Max. weight of workpiece | 2800 lbs |

| Motors | Details |

| Main motor ( Pre-wired 220 V / 3 ) | 15 HP, 220/440 V, 3 phase |

| Rapid traverse motor | 1/3 HP, 220/440 V, 3 phase |

| Coolant pump motor Pre-wired 220 Volt / 3 ) | 1/8 HP, 220/440 V, 3 phase |

| Machine net weight | Details |

| GT-3280 | 9,350 lbs |

| GT-32120 | 9,850 lbs |

| Overall dimensions | Details |

| GT-3280 L x W x H | 142" x 46" x 68" |

| GT-32120 L x W x H | 182" x 46" x 68" |

Standard Equipment included for

GMC Heavy Duty Lathes Model # GT-3280 and GT-32120:

· Free Taper turning attachment,

, installed

· Automatic longitudinal kick-out carriage stop system for GT-3280 only

· 16 inch 3-jaw chuck

with top reversible jaws

· 20 inch 4-jaw chuck with top reversible jaws

· 25 inch Face plate

· 10 inch drive plate

· 6-3/4 â?? 12-1/2 inch large steady rest with roller jaws

· 1-3 inch follow rest

· Removable gap

· 4-way tools post

· Foot brake

· Halogen Work light

· Coolant system

· Oil pump on apron for lubrication to all ways and leadscrews

· Full length rear splash for GT-3280 only

· Section splash guard on Apron for GT-32120 only

· (2) dead centers and (1) reducing sleeve

· Thread chasing dial

· Tool box